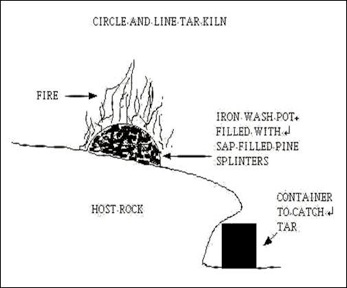

A large and Distinctive tar kiln is located on the property. Such kilns consisted of a large trench dug in the ground, with a sloping base leading to a drain hole which opened to a smaller, but deeper catch basin.

The larger trench was filled with roots, logs, slabs, or boards from long leaf pines. There was evidently some art to positioning the wood, and the whole thing was covered with dirt and green pine branches. it was then fired from the upper end, opposite the drain hole, and allowed to smolder, much like a charcoal kiln. The heat melted the volume of resin from the pine, and it ran through the drain hole into the catch basin.

This tar was dipped out into barrels and shipped to the coast where it was used to seal the seams of wooden ships. Other uses may have existed. These kilns were often fired more than one time, which contributed to the sizable build up of tar on the walls of the pit and catch basin. it is not known when this kiln, or pit was fired.

The tar kiln opening, the bottom of the inner retort can be seen

Tar Kilns

Tar from the Tar Kiln

The Tar Kiln on Edwin Patterson’s property